Research

Flexible and Transparent

> Research > Advanced Display > Flexible and Transparent

> Research > Advanced Display > Flexible and Transparent

Transparent and flexible display

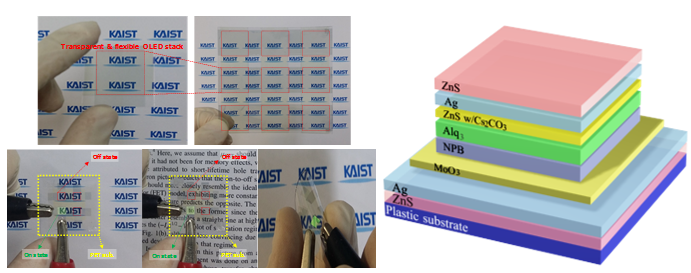

In recent years, the transparent and flexible display is in the best interest of researchers as future display. Organic light-emitting diodes (OLEDs), in particular, are considered promising candidates for advanced displays due to their capability to satisfy both transparent and flexible properties. However, OLEDs typically consist of brittle indium tin oxide (ITO) and metal film of low transparency, so alternative electrodes are required to produce transparent, flexible OLEDs (TFOLEDs). On the other hand, there is a kind of electrode that consists of a high refractive index dielectric layer/ metal film/ high refractive index dielectric layer (multilayer). It exhibits high transmittance, high flexibility, and low sheet resistance. So we propose a TFOLED structure using multilayer electrodes as both anode and cathode at the same time

[TFOLED with optimized multilayer electrode and structure]

Flexcible electrode

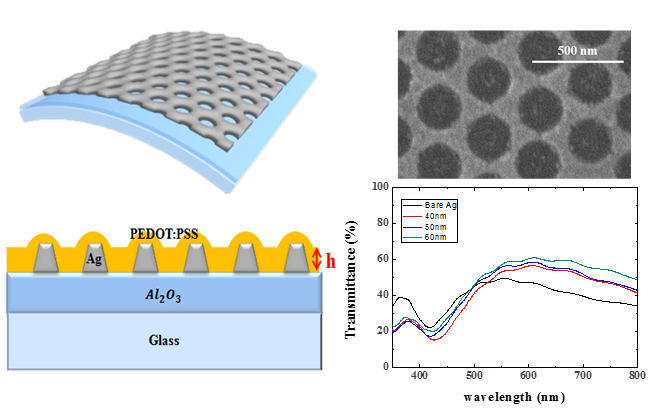

In the display devices, electrodes are essential for transmitting pulses. Especially in transparent display devices, the electrodes should be transparent in order to obtain the high transparency. Also, the transparent electrodes require the high conductivity. Conventionally used transparent and conductive materials such as indium tin oxide (ITO) have certain problems that must be resolved before they are adapted to large-area and flexible display devices. These problems include their relatively high resistance and poor flexibility. With these reasons, we have investigated novel transparent electrodes to replace ITO electrodes by using multilayered structure, silver nanowire, and perforated metal film.

[Multilayered electrode with TCO and thin metal layers]

[Metallic nanohole electrode]

Thin-film encapsulation

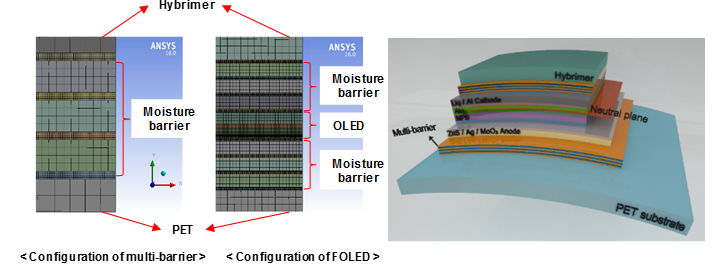

Nowadays, the development in display technology is becoming faster, and as such, the display paradigm is rapidly shifting to flexible displays. Even though OLEDs have many advantages, there are some significant disadvantages. The organic materials in OLEDs are very sensitivity to moisture and oxygen which cause reliability problems. So the moisture barrier for flexible OLEDs (FOLEDs) requires a complicated and longer diffusion path as well as flexibility. We strategically introduced a nanolaminate structure to the multi-barrier system to satisfy these conditions. The hybrid nano-stratified moisture barrier has not only a low WVTR compared to normal multi-barriers but also more flexibility than that of general nanolaminate barriers.

[Hybrid nano-stratifide moisture barrier for FOLEDs]

Enhancing the mechanical property through finite elements method

There is currently substantial interest in developing flexible organic electronic devices. The thin-film encapsulation technique is recognized as a promising alternative to glass-lid encapsulation because it prevents gas permeation and provides mechanical flexibility. Even though FOLEDs are implemented on flexible substrates with thin-film encapsulation, some components are still vulnerable to mechanical strain, such as ITO electrodes and inorganic materials of multi-barrier systems. We focus on enhancing robustness against cyclic bending stress after thin film encapsulation of flexible OLEDs. Strategies to optimize the entire multilayer structures with theoretical prediction of neutral axis behavior based on the finite-elements method analysis was discussed.

[FEM simulation for enhancing the bending characteristics]